Cold Chain Logistics: Ensuring Product Integrity

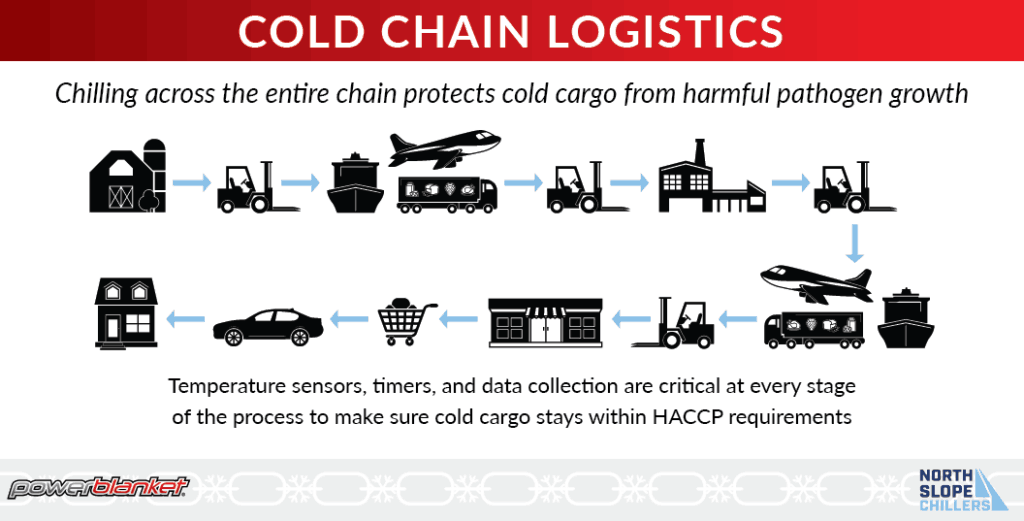

The cold chain logistics industry plays a critical role in ensuring the integrity of temperature-sensitive products, such as food, pharmaceuticals, and biologics, during transportation and storage. The process of cold chain logistics involves the use of specialized equipment and vehicles to maintain a consistent refrigerated temperature throughout the supply chain, from the manufacturer to the end-user.

The Importance of Cold Chain Logistics

Cold chain logistics is essential for preserving the quality and safety of temperature-sensitive products. Without proper refrigeration, these products can spoil or become contaminated, leading to serious health risks and significant financial losses. The World Health Organization (WHO) estimates that up to 30% of vaccines can be damaged or destroyed due to inadequate cold chain management, resulting in reduced effectiveness or even complete failure of vaccination programs.

In addition to the health risks, ineffective cold chain logistics can also lead to significant economic losses. Spoilage of perishable goods can result in lost revenue, damage to reputation, and legal liabilities. In the pharmaceutical industry, the loss of a single shipment of temperature-sensitive medication can result in financial losses of up to $1 million.

Challenges in Cold Chain Logistics

Cold chain logistics is a complex and challenging process, requiring the coordination of multiple stakeholders, including manufacturers, logistics providers, and warehousing and distribution centers. Some of the key challenges in cold chain logistics include:

- Temperature Control: Maintaining a consistent refrigerated temperature throughout the supply chain is critical for product integrity. Temperature excursions, even for a short period, can compromise product quality and safety.

- Infrastructure: In many parts of the world, the lack of adequate cold chain infrastructure, including refrigerated transportation and warehousing, hinders the effective distribution of temperature-sensitive products.

- Cost: Cold chain logistics is a costly process, requiring significant investments in specialized equipment, vehicles, and facilities.

- Regulatory Compliance: Cold chain logistics must comply with strict regulations and guidelines, including the International Air Transport Association (IATA) and the United States Pharmacopeia (USP).

Innovations in Cold Chain Logistics

Despite the challenges, the cold chain logistics industry has seen significant innovations in recent years, including:

- Internet of Things (IoT) Technology: IoT sensors and monitoring systems enable real-time tracking and monitoring of temperature-sensitive products, providing visibility and control throughout the supply chain.

- Refrigeration Systems: Advances in refrigeration systems, such as cryogenic refrigeration and phase change materials, provide more efficient and cost-effective temperature control.

- Sustainable Solutions: The use of sustainable fuels, such as biofuels, and eco-friendly packaging materials reduces the environmental impact of cold chain logistics.

- Data Analytics: Advanced data analytics enables the optimization of cold chain logistics, reducing costs, and improving efficiency and product integrity.

Best Practices in Cold Chain Logistics

To ensure product integrity, cold chain logistics providers must follow best practices, including:

- Temperature Monitoring: Continuous temperature monitoring throughout the supply chain to detect any temperature excursions.

- Proper Packaging: Using specialized packaging materials to protect temperature-sensitive products during transportation and storage.

- Training and Education: Providing training and education to personnel on cold chain logistics procedures and protocols.

- Risk Assessment: Conducting regular risk assessments to identify potential vulnerabilities in the cold chain.

Conclusion

Cold chain logistics is a critical component of the supply chain, ensuring the integrity of temperature-sensitive products. Effective cold chain logistics requires careful planning, specialized equipment, and trained personnel. By adopting innovative solutions and following best practices, cold chain logistics providers can ensure the safety and quality of temperature-sensitive products, reducing risks and costs, and improving public health.

Keywords: Cold chain logistics, temperature-sensitive products, pharmaceuticals, biologics, food, refrigeration, logistics, transportation, storage, supply chain, product integrity, quality, safety, risk assessment, innovation, sustainability, data analytics.

Meta Description: Cold chain logistics is crucial for maintaining product integrity. Learn about the importance, challenges, and innovations in cold chain logistics, and discover best practices to ensure the safety and quality of temperature-sensitive products.

Header Tags:

- H1: Cold Chain Logistics: Ensuring Product Integrity

- H2: The Importance of Cold Chain Logistics

- H2: Challenges in Cold Chain Logistics

- H2: Innovations in Cold Chain Logistics

- H2: Best Practices in Cold Chain Logistics

- H2: Conclusion